MS /FRP Compact Portable Type STP

Technical Details MGP– MBR/SBR/ASP is an indigenous technology developed to meet stringent treated water quality for sewage water and industrial effluent. MGP - MBR is a membrane reactor based design for biological treatment of waste water. MGP - MBR operates on the principle of biological/bacterial process followed with membrane filtration. Raw untreated wastewater is sent to MGP - MBR reactor requires a bar screen to prevent any larger debris, plastics etc. clogging the reactor. MGP - MBR module is a bio reactor fitted with necessary components like air diffuser and filtration membrane with a pore size ranging from 0.1 micron to 0.01 micron. Residence time of waste water within the reactor is controlled by drawing rate from the membrane module. Treated water is drawn from the reactor using suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content and free from suspended solids. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge as per the requirement (Capacity 5kld to 500kld).

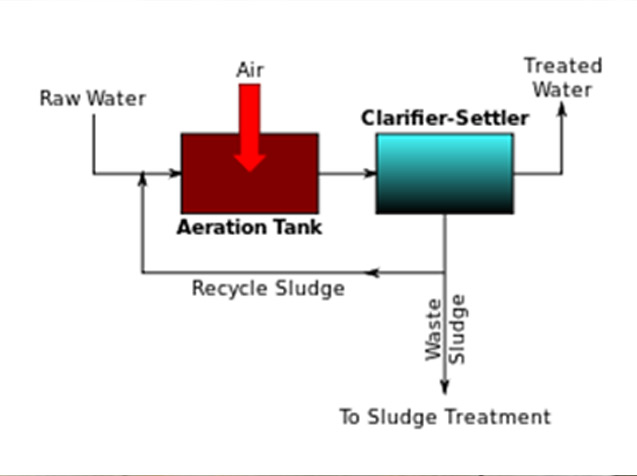

Conventional ASP technology (ASP Technology)

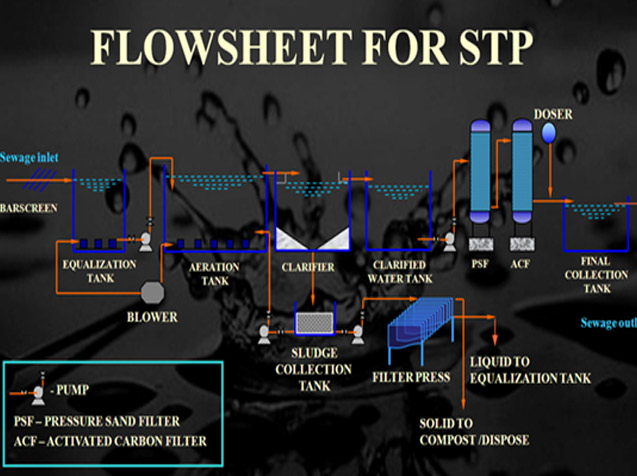

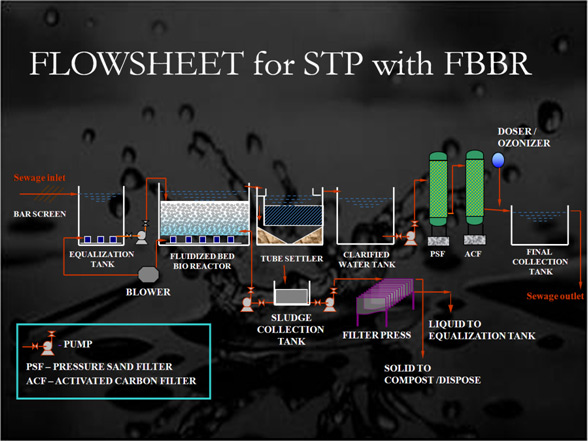

Technology and Process DescriptionPrimary Treatment

Secondary Treatment

Tertiary Treatment

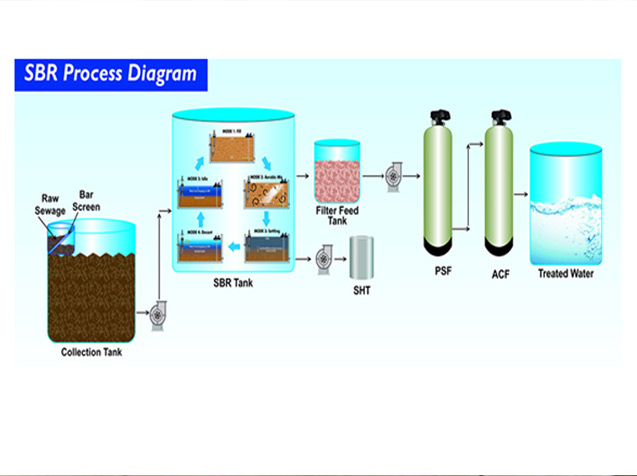

Sequential Batch Reactor (SBR Technology)

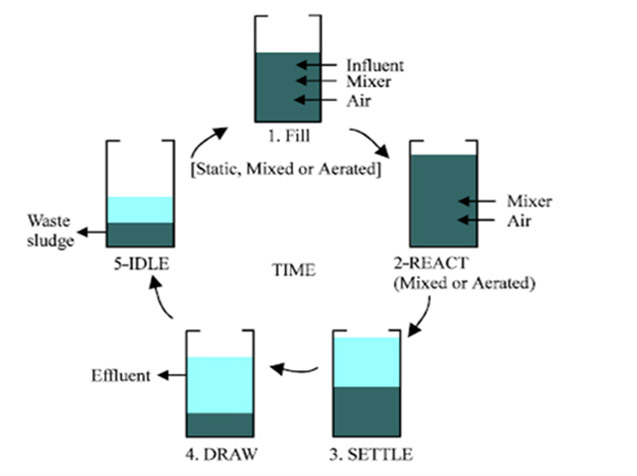

Technology and Process DescriptionThe Sequencing Batch Reactor (SBR) is an activated sludge process working in a batch mode with aeration and sludge settlement both occurring in the same tank. This leads to a reduction in civil costs and less space is required as several steps are occurring in the same tank There are five stages in the treatment process

Fill

React

Settle

Decant/ Draw

Idle

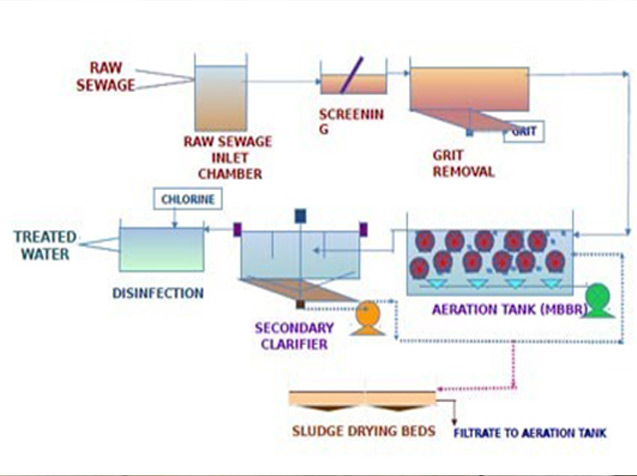

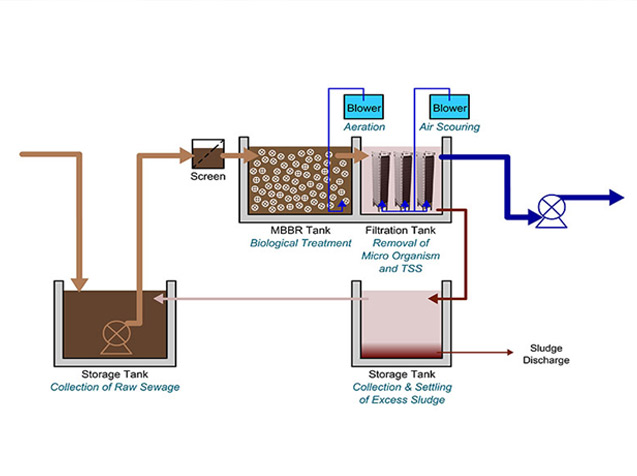

Moving bed bio Reactor (MBBR Technology)

Technology and Process DescriptionTIt contains the Bio pack and tube pack media to enhance the surface volume for Microbial growth.

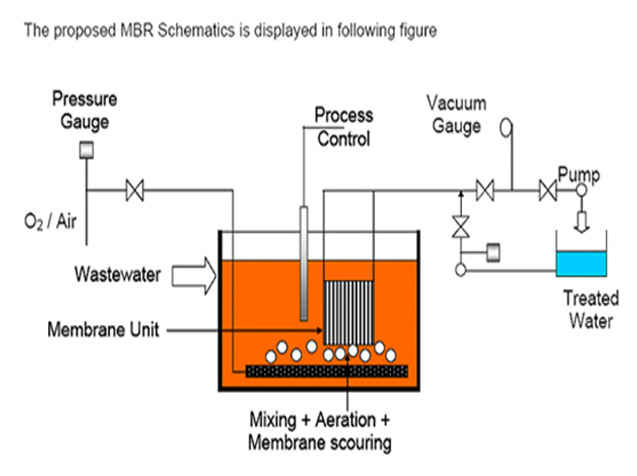

Membrane Bio Reactor (MBR Technology)

Technology and Process DescriptionMBR PROCESS

Pre-Treatment

Pre Screen

Oil & grease removal

Sand removal & fine screen

Bio Reactor

Submerged membrane/Airlift membrane

Air blowers diffuse air to the wastewater

Balance sludge discharge through pump

Clear water will be permeated out by self priming pump at vacuum pressure through MBR Modules

The Sequencing Batch Reactor (SBR) is an activated sludge process working in a batch mode with aeration and sludge settlement both occurring in the same tank. This leads to a reduction in civil costs and less space is required as several steps are occurring in the same tank There are five stages in the treatment process

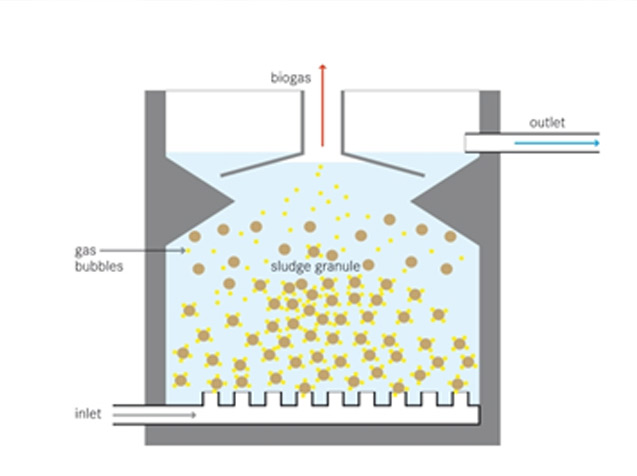

Up flow anaerobic sludge blanket (UASB Technology)

UASB uses an anaerobic process whilst forming a blanket of granular sludge which suspends in the tank. Wastewater flows upwards through the blanket and is processed (degraded) by the anaerobic microorganisms. The upward flow combined with the settling action of gravity suspends the blanket with the aid of flocculants. The blanket begins to reach maturity at around three months. Small sludge granules begin to form whose surface area is covered in aggregations of bacteria. In the absence of any support matrix, the flow conditions create a selective environment in which only those microorganisms capable of attaching to each other survive and proliferate. Biogas with a high concentration of methane is produced as a by-product, and this may be captured and used as an energy source, to generate electricity for export and to cover its own running power. The technology needs constant monitoring when put into use to ensure that the sludge blanket is maintained, and not washed out (thereby losing the effect). The heat produced as a by-product of electricity generation can be reused to heat the digestion tanks.

Consistent supply of treated water

Low operating & maintenance cost

Minimum foot print area

Low power consumption

Minimum use of chemicals

Focus on ease of maintenance while designing

Trained team for installation & after sales service

Environment friendly systems

Plants with parameters meeting PCB norms

Overcomes factors of space and height constraints

MGP ADVANTAGE FOR STP

Ready to use Systems

Easy to Install

Fast Delivery

Operational Support and Commissioning